Do you need motion solution to build your 3D machine? Or your pick and place? With this modular system, you will be able to create different solutions for XYZ and much more. Let me introduce you the Barch linear guide rails belt drive with smart design, a complete new solution easy to assembly different axis and structures for hundreds of applications.

BCX series the flexible design

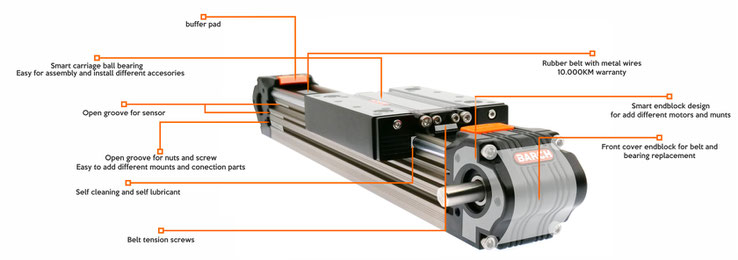

Smart body profile design: a body profile design with different open grooves that allow you add sensors, cameras, connection parts, mounts and so much on. The best way to build, assembly and install in a fast way without lost accuracy and with low vibration.

Smart carriage design: With all the possibilities to add various devices, vacuum pick and place, laser heads, 3D extruders, drill devices, rotary devices and so on.

Smart endblock design: With an endblock that allows adds a different size of servomotors, stepper motors or speed reducers in multiple positions.

Customizable length: with a maximum length of 6 meters our linear guide rails can be produced in different sizes in a customized way. All depending on the requirements of our clients.

Load capacity from less than 1 kilograms to a maximum 35KG

Write a comment

Eric Manneschmidt (Wednesday, 15 July 2020 12:10)

I am interested in making a XYZ motorized similar to what was illustrated in the video. I need to be able to basically make a motorized copy stand where I can control the camera with the Z axis for field of view and focus while using XY for positioning over the sample. I probably need a maximum XY range of ~6" in each direction and a Z distance of ~16".

I also need controller and power supply appropriate for each with fairly fine control on each axis for proper alignment and Z for focus. If there is the capability for a digital readout of position, that would be nice, but not essential.

The use I have for this is in a radiation area, so the cabling and controls will need to be 30 ft away, so I will need an extension for the cables which can be passed through a wall and then connected to the various slide motors.

The only load to consider other than the weight of the actuators is the camera which will be a standard DSLR (Nikon) and is probably under 5 lbs.

Mohanadas Balasingham (Monday, 19 April 2021 02:25)

I need your expertise to make an XY modular gantry with a picker that can go up and down the Y beam. Size 6m x 3m